Artificial Intelligence in 3D Printing Model Creation: How AI Assists Designers

Artificial Intelligence in 3D Printing Model Creation: How AI Assists Designers

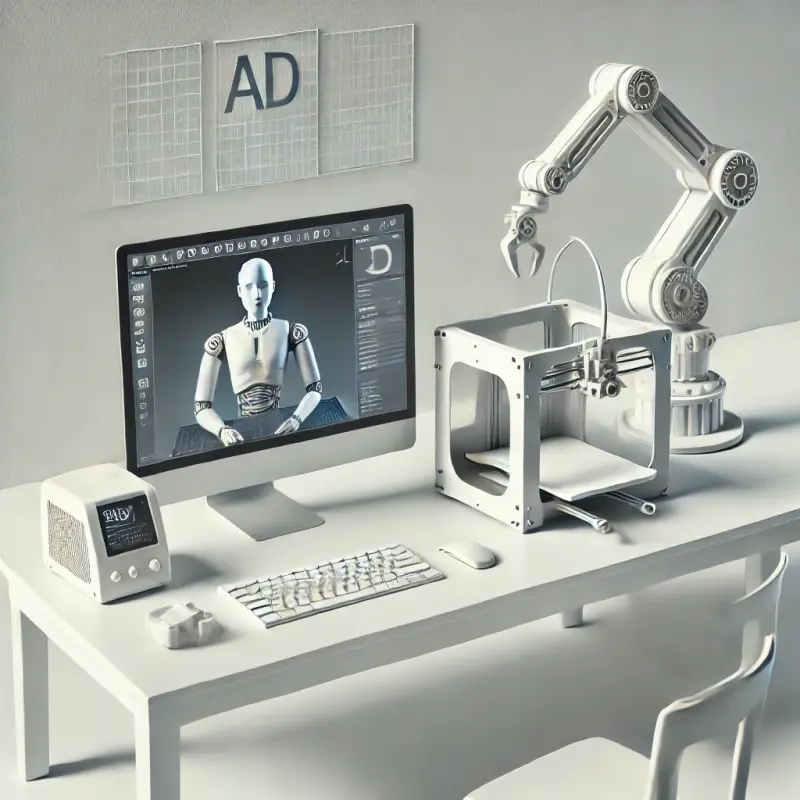

In the world of 3D printing, where precision, efficiency, and creativity are key, artificial intelligence (AI) has emerged as a game-changer for designers. Through powerful algorithms and advanced processing capabilities, AI supports designers by automating complex tasks, optimizing designs, and enhancing model quality in ways that were once unthinkable. This article explores the role of AI in 3D printing design, delving into the technologies and methods that streamline workflows and push the boundaries of what’s possible in model creation.

How AI Transforms the 3D Design Process

The integration of AI into 3D design and printing has streamlined various stages of model creation, from conceptual design to final print optimization. Traditional 3D modeling often requires significant time and expertise, but with AI, the process becomes faster and more intuitive. AI algorithms are capable of recognizing patterns, predicting optimal design structures, and even generating complete models based on specific inputs or templates. This doesn’t replace the designer’s role but instead augments their capabilities, allowing them to focus on creativity while AI handles routine calculations and adjustments.

Automated Geometry and Shape Recognition

One of the standout features of AI in 3D modeling is its ability to automatically recognize and adapt complex geometries. AI tools analyze the shape and structural needs of a model and can recommend adjustments or automatically alter geometry to improve stability, strength, or material efficiency. This is especially useful in fields such as architecture, product design, and healthcare, where intricate shapes and structures are crucial. For example, in medical applications, AI helps to create customized prosthetics by adjusting model geometries to perfectly fit individual anatomical features.

Optimizing Models for Material Efficiency

AI-driven 3D printing software often includes tools for material optimization, which reduces costs and minimizes waste. By analyzing the necessary strength and weight distribution, AI algorithms can suggest ways to redesign a model that uses less material without compromising on durability. This not only benefits the designer economically but also promotes sustainable practices in 3D printing. Companies are increasingly adopting AI tools to design lighter, yet equally robust parts for manufacturing, aerospace, and automotive industries, where reducing material costs and conserving resources are top priorities.

Streamlining Workflow for Faster Prototyping

With the demand for rapid prototyping on the rise, AI in 3D printing enables quicker iteration cycles. Previously, designers might have had to manually test various design options or reconfigure parts to fit different printing methods. AI-powered tools now provide instant feedback on design feasibility, printability, and durability, enabling designers to make informed adjustments quickly. This real-time assessment significantly reduces trial-and-error time and allows for faster transitions from concept to prototype, speeding up the overall development timeline.

AI-Based Generative Design

Generative design is a powerful AI-driven approach that generates multiple model variations based on specified parameters. Designers input requirements, such as weight, strength, material, or size constraints, and the software produces a range of viable designs to choose from. This technology empowers designers to explore new possibilities without manually creating each model variation, fostering greater creativity and exploration. In fields like engineering and industrial design, generative design is instrumental for developing complex structures that are both functional and innovative.

Error Detection and Quality Assurance

Errors in 3D printing, like structural weak points or overlapping surfaces, can lead to costly and time-consuming mistakes. AI algorithms analyze models in-depth to detect potential errors before printing begins. By flagging these issues in the design phase, AI significantly enhances quality assurance, saving both time and resources. This proactive error detection is essential for industries where precision is paramount, such as aerospace and healthcare, where even minor flaws can have serious consequences.

Enhancing Customization and Personalization

Artificial intelligence also empowers designers with advanced customization tools, allowing them to tailor models to specific needs or preferences with precision. This level of customization is particularly valuable in sectors such as fashion, consumer goods, and medical devices. For example, AI can analyze customer feedback and preferences to create unique product variations that cater to individual tastes. In healthcare, AI-based 3D modeling enables the creation of personalized implants and prosthetics that perfectly fit a patient’s anatomy, enhancing comfort and functionality.

AI in Parametric Modeling

Parametric modeling, a process where design elements are defined by parameters or rules, is a common technique in 3D modeling. With AI, parametric modeling becomes more powerful and intuitive. Designers can set parameters for different aspects of a model, such as height, width, thickness, or curvature, and the AI tool will adjust the design accordingly. This is particularly useful for creating models that require precision or adhere to specific guidelines. By integrating AI, parametric modeling allows for quick adjustments and real-time feedback, making it easier to develop complex, rule-based designs.

Simulation and Stress Testing

AI enhances the simulation capabilities of 3D printing software, allowing designers to test their models under various conditions before they go to print. This is especially valuable in fields that demand durability and resilience, such as automotive and aerospace engineering. AI-based simulations can predict how a model will react under stress, load, or environmental factors, offering insights that might otherwise require physical prototypes. This not only saves time and materials but also improves the accuracy and reliability of the final product.

Supporting Creativity and Experimentation

AI-driven design tools do more than just optimize efficiency; they also open up new realms of creativity and experimentation. Through machine learning algorithms, AI systems learn from previous designs and user preferences, gradually improving in their ability to suggest ideas and modifications. Some AI tools even offer ‘creative suggestions’ based on patterns they recognize in the designer’s work, encouraging exploration of unconventional designs and innovative concepts. This ability to experiment freely without the constraints of manual adjustments can be inspiring, helping designers push creative boundaries.

Augmented Reality (AR) and AI in 3D Design

As augmented reality (AR) and AI technologies converge, designers can experience their models in immersive environments before they are printed. AI-powered AR tools can project virtual 3D models into real spaces, allowing designers to see how a product might look in a specific setting or assess its spatial dimensions in context. This capability is particularly valuable in interior design, architecture, and consumer product design, where spatial awareness and aesthetics are crucial. By combining AI’s analytical power with AR’s immersive potential, designers gain a deeper understanding of their creations and make more informed decisions.

Collaborative Design Environments

AI facilitates collaborative workflows in 3D design by making it easier for teams to work together on a single project. Cloud-based 3D design platforms that incorporate AI allow multiple users to access and modify designs in real-time, with AI tools providing version control, suggestions, and error checks. This collaborative environment is especially beneficial for large-scale projects or companies with distributed teams, as it ensures that everyone is working on the latest version and that any issues are quickly identified and resolved.

Challenges and Future Prospects of AI in 3D Printing Design

While the benefits of AI in 3D model creation are extensive, there are also challenges to consider. One key concern is the potential over-reliance on AI, which could lead to a loss of manual design skills among professionals. Additionally, AI algorithms require large datasets to function optimally, which can be a barrier for smaller firms that may not have access to extensive design data. Ethical considerations, such as data privacy and the potential bias in AI-generated designs, also need to be addressed as AI becomes more integrated into creative fields.

Looking forward, as AI technology evolves, its applications in 3D printing design will likely become even more sophisticated. Advances in natural language processing (NLP) could enable designers to use voice commands or simple language prompts to instruct AI in modifying models. Furthermore, with the rise of generative adversarial networks (GANs) and reinforcement learning, future AI tools may develop even more autonomous design capabilities, creating models that are optimized for function, aesthetics, and material efficiency.

Conclusion

Artificial intelligence is reshaping the landscape of 3D model creation, making it more accessible, efficient, and innovative. By automating routine tasks, enhancing customization, and facilitating rapid prototyping, AI empowers designers to focus on the creative and conceptual aspects of their work. As AI continues to develop, its role in 3D printing design will likely expand, introducing new tools and possibilities that further enrich the creative process. For designers, embracing AI means gaining a powerful partner in innovation—one that enhances their abilities, fosters collaboration, and paves the way for exciting developments in 3D design and printing.

Articles

Join our notification list to receive timely updates on the latest and most captivating articles in your mailbox.